Bare aluminum systems S1 & S3 – flexible protection solutions for every industrial application

Our aluminum solutions complement EcoSteel where lightweight, flexible, and cleanly integrated shielding is required. S1 as a drop-in panel system and S3 as a direct panel system cover all typical requirements, from rapid conversion to line-compatible permanent installation – fillable with mesh, PETG, and PC (including green/red for welding protection). Both systems are designed to meet the requirements of DIN EN ISO 14120 as a separating protective device

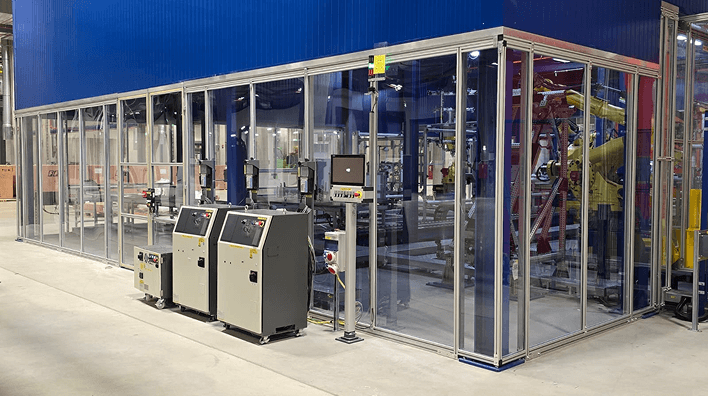

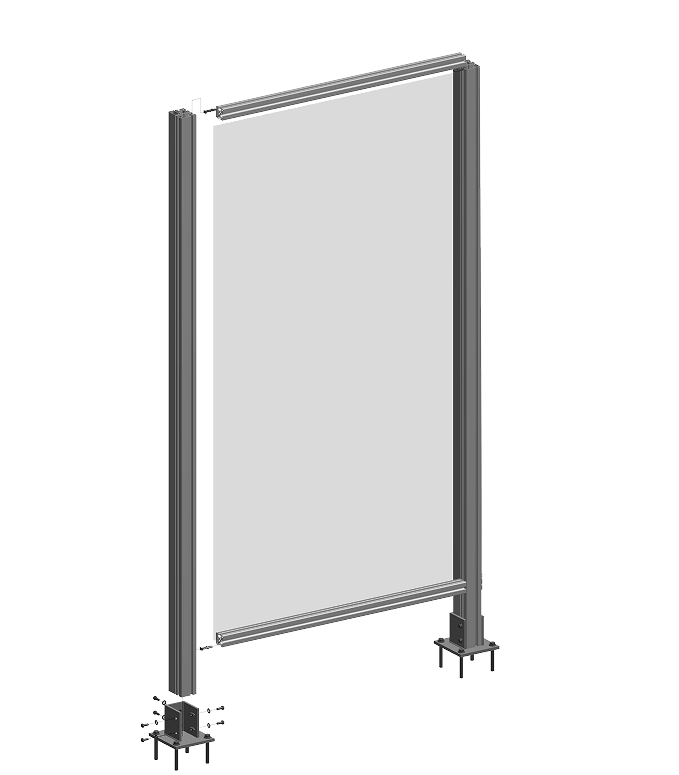

S1 – Drop-in panel system

S1 is an internal drop-in panel system: panels are hooked into the posts via angle connectors, locked, and released again in minutes if required. This makes S1 the ideal solution for maintenance-intensive areas, conversions, and temporary zones.

Standard alignment:

S1 is designed to meet the requirements of DIN EN ISO 14120 as a separating protective device (execution-specific design in the project).

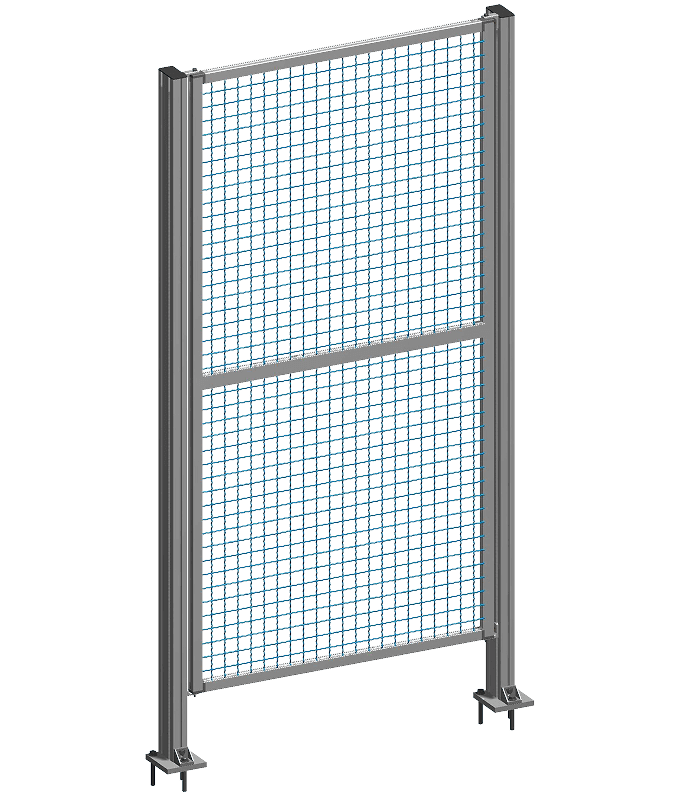

Construction & Geometry

Posts: 90 × 45 mm, groove 10 – high compatibility with standard T-nuts and accessories

Frame: 30 × 30 mm

Angle-variable mounting: infinitely adaptable to non-90° corners thanks to groove profiles (e.g., bypassing columns, machine contours, inclined inlets)

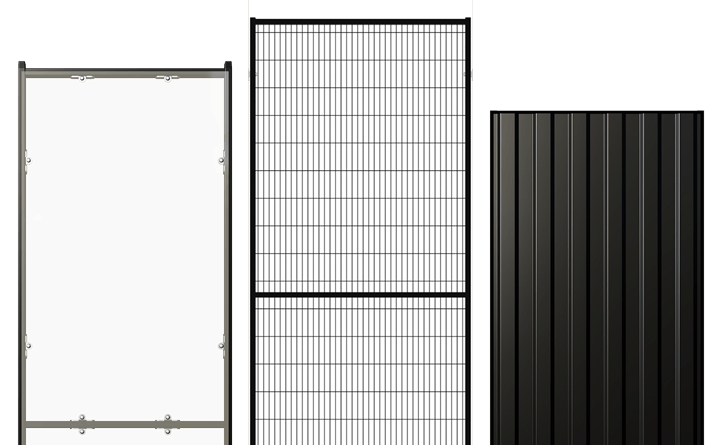

Fillings

- Mesh (high visibility & ventilation)

- PETG (transparent impact and splash protection)

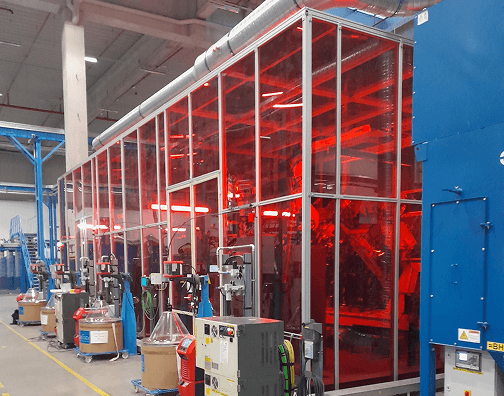

- PC Green/Red (welding protection/privacy screen; colored marking of zones)

Advantages in application

Fast assembly/disassembly: hanging instead of complete screwing

Layout flexibility: angle-variable corners without special components

Service-friendly: individual panels can be replaced with minimal tools

Clean integration: slim profiles, low mass – low roof and load reserves required

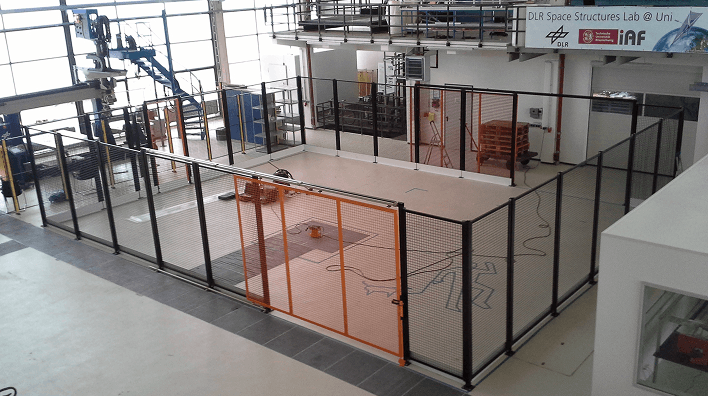

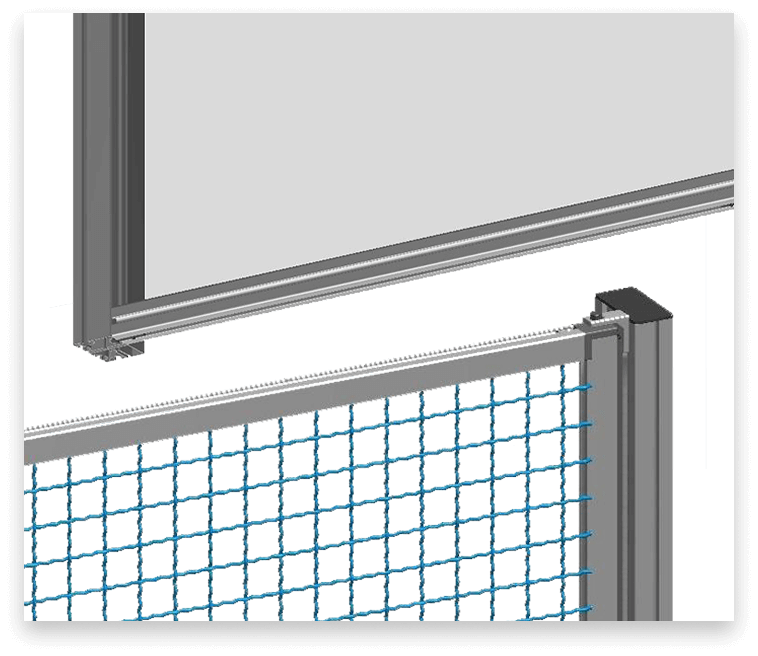

S3 – Drop-in panel system

S3 is a direct panel system: the panels are screwed directly to the posts without separate outer frames – “arranged in a composite”. This reduces components, increases line rigidity and ensures homogeneous, low-gap transitions.

Construction & service panel

Standard alignment:

S3 is designed to meet the requirements of DIN EN ISO 14120 as a separating protective device (project-specific dimensioning/safeguarding).

Construction & Geometry

Posts: 60 × 80 mm, groove 8 – compact, torsion-resistant, accessory-compatible

Direct connection: panels screwed directly to posts, no outer frames required

Replaceable panel (service): a separate frame is provided at critical points – guided at the bottom via angle bracket, secured at the top with special fastening. This keeps the line closed, but maintenance exits can still be opened quickly.

Fillings

- Mesh (high visibility & ventilation)

- PETG (transparent impact and splash protection)

- PC Green/Red (welding protection/privacy screen; colored marking of zones)

Advantages in application

- Reduced components for fast, economical assembly

- High composite rigidity over the line course

- Low-gap to gap-free design possible at transitions

- Maintenance-friendly, defined replaceable panel for quick interventions

Fillings – Functional Variety

In addition to mesh fillings, we offer three other filling variants for special requirements. All fillings are fully compatible with the aluminum system and can be flexibly combined or retrofitted.

PETG filling

- UV-resistant, suitable for laser workstations

- Very impact and scratch resistant

- ISO EN 25980-compliant

- Protection against sparks and optical radiation

Polycarbonate filling (PC)

- Extremely break-proof

- Available transparent or tinted

- Suitable for high mechanical loads

Sheet metal filling

- Completely closed – ideal when privacy is required

- Protection against dust, chips, sparks

- Highest structural strength

Doors, gates & handling from a single source

For safe and flexible access, we offer a variety of door solutions that can be optimally integrated into our safety fence system. Depending on the requirements for space, operation and safety level, the following variants are available:

Portfolio

Single & double doors:

The classic solution for regular access.

Multi-folding doors:

Space-saving and ideal for large openings.

Sliding doors:

For convenient operation even in confined spaces.

Swing flaps:

For quick, uncomplicated passage.

Lift gates:

For automated and particularly convenient solutions. (mechanical, electrical or pneumatic)

OUR PROMISE, YOUR ADVANTAGE

Why two systems?

- S1 (drop-in panel) scores with conversion, maintenance, angle requirements and quick adaptation.

- S3 (direct panel) impresses in continuous lines with few components, low-gap appearance and high composite rigidity.

Both systems can be equipped with mesh, PETG or PC (green/red) – depending on the view, process or protection requirement. Both are designed to meet the requirements of DIN EN ISO 14120 and are dimensioned and implemented on a project-specific basis.

Picture gallery S1 & S3